C.R. Onsrud

C.R. Onsrud CNC Machines are found in the manufacturing facilities of some of the largest brands of the world. C.R. Onsrud brings value and performance to their bottom line, as they've been around for decades cutting wood, metals, plastics, composite materials, and much more! NEVER COMPROMISE ON VALUE.

Request a Quote

Use the menu at the left to navigate to a specific series or line of machine

3-Axis Moving Gantry // Mate Series

C.R. Onsrud's Mate series is the smallest CNC machine in the C.R. Onsrud line-up. But don't be fooled, this CNC router, boasts rigid frame construction, the smoothest, most responsive drive mechanisms in the industry, and many more of the top-end features you'll find on our bigger models. For more information on this line click HERE.

121M

145M

3,050M

3-Axis Moving Gantry // Tech Series

3-Axis Moving Gantry // Pro Series

A “Moving Gantry” CNC router, when made correctly, is particularly well suited for panel and sheet processing applications. Here, the table stays fixed, while the bridge moves over its surface. This design saves valuable floor space, keeps the price down, allows for useful options (such as tool changers and multi- spindle drilling heads) and offers incredible throughput and productivity. This design is not normally as well suited to the heaviest cutting and highest material removal rates because moving steel frames, on any CNC router design, have a difficult time absorbing many of the additional cutting vibrations created by the heavier applications. However, if it is built and designed correctly, like our Pro series, it can easily break down full sheets of 1-1/2" thick plywood, laminates, veneers, or 1/4" thick aluminum jig plate, at super fast feed rates, under continuous duty conditions and handle heavier applications on a limited or multi-pass basis. Panel processors and cabinetmakers love the flexibility and production capabilities that the Pro Series design offers. Sign makers and plastics fabricators typically like moving gantry machines because of the lower initial purchase price, while solid surface and aluminum sheet fabricators like the large table-size-to-cost ratio. For more information on this line click HERE.

145G

193G

333G

429G

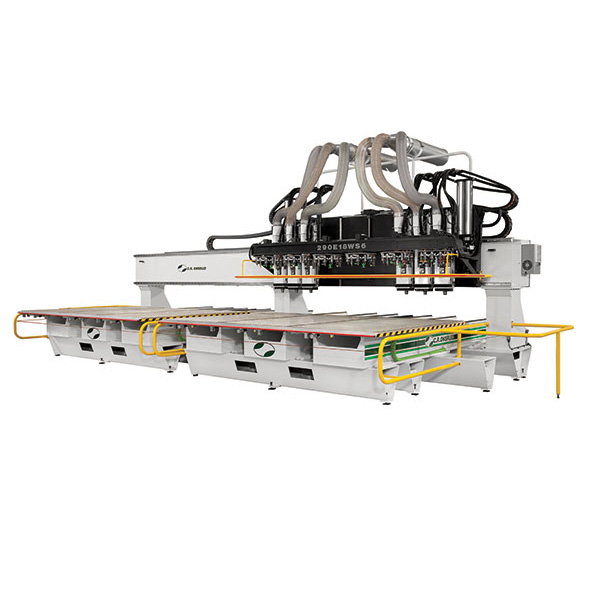

3-Axis Moving Gantry // Wide Pro Series

The one-piece, thick-wall steel base of the Wide Pro Series was specially engineered with internal steel reinforcements. It is designed to handle the extreme weight of large blocks of non-ferrous metal, oversized tooling or fixtures for composites, and sheet metal parts. You will be able to stack cut aluminum skins, or even the large and thick assemblies we tackle in the RV, marine, and aircraft industries. After being welded into a single structure, the machine base is heat treated and controlled cooled to create a stress free, normalized, and lasting machining platform. Then the precision machining for all of the critical components is accomplished in one set-up, with all of the operations performed on the same face, to guarantee machined-in accuracy and stability. This base also incorporates the top-rail design of the Pro Series, which allows for shorter and stubbier one-piece steel vertical columns, which are more rigid and have more leverage over the bridge than other side rail designs. The result is a high precision machine that handles the largest workpieces, deals with the heaviest materials and tooling, offers unique automation and material handling options, and provides the best possible cost per table size relationship available. For more information on this line click HERE.

Wide Pro 6

Wide Pro 8

Wide Pro 10

Wide Pro 12

3-Axis Moving Gantry // Roller Hold Down Series

C.R. Onsrud Roller Hold Down routers provide the ultimate flexibility in routing single sheet, stacked sheet, small part, large part, rollers engaged or disengaged, giving you the capability of multiple CNC machines for the cost and footprint of one. These machines feature 2 rollers on each side of the cutting spindle(s), automatically extending & retracting rollers as they roll off the cutting table, for holding down warped sheet stock or stacked sheet routing. Each roller's pressure can be regulated to prevent premature wear due to slamming rollers into the table & material. Additionally, the roller hold down design assists in the ability to machine narrow, low surface area, parts. Roller Hold Down is available in either our cast-iron fixed bridge moving table design (similar to our S-Series) with efficient material handling, our even more efficient twin table moving gantry design (similar to our Pro Series), or our most efficient continuous triple table moving gantry design. For more information on this line click HERE.

145G18R

241G18R

288G18R

98S18R

3-Axis Moving Gantry // Custom Machines

C.R. Onsrud's Custom Machines is ...For more information on this line click HERE.

3-Axis Fixed Bridge // Super Duty Series

72C

96C

98C

122C

146C

3-Axis Fixed Bridge // Extreme Duty Series - 1 Spindle Standard

Designed and built to be the heaviest, fastest, and highest performing machines available in the world at any price, the Onsrud Extreme Duty Series CNC Router is truly our "No-Compromises" model. We start with the largest standard cast iron frame offered anywhere in our marketplace today. The massive cast iron bridge on the HD Series has over double the cast iron of even our legendary C Series models. The cast iron frame is then mated to our one-piece, self-supportive, heat-treated, stress-relieved and normalized, internally-reinforced, thick-walled, steel base for unrivaled weight, mass, rigidity, durability, feeds and speeds. We then use only the highest-end, top-shelf, non-proprietary and readily available components in the world today to offer you the most technologically advanced Onsrud ever. Many of the standard features on the Extreme Duty may be options and/or upgrades on our other C.R. Onsrud models, but they are not even offered by the competition. When you require unrivaled feed rates, machining speeds and rapid traverse rates, when your jobs demand the ability to run the largest diameter tool and take the deepest, heaviest cuts in the most dense and unforgiving materials, when you insist on the highest possible accuracy and repeatability, when you want the best possible machined finish that tooling can provide... if you want the lowest operating maintenance cost, the lowest number of occurrences and the shortest duration of downtime... when you want to have the assurance and satisfaction of knowing beyond a shadow of a doubt that you have purchased the biggest, heaviest, best built, fastest, most powerful, most durable and most productive machine available on the market today, then the C.R. Onsrud Extreme Duty Series is for you! For more information on this line click HERE.

98HD

122HD

148HD

194HD

244HD

3-Axis Fixed Bridge // S Series

: The S-Series is designed for applications that require the fixed bridge performance of our popular Super Duty Series, but are better served by the table(s) moving the long direction under the bridge. This makes our S-Series the direct alternative to our Super Duty Series. These two series of machines share almost all of their major components: from the control, to the spindle, the electronics, the mechanical linear motion systems, the bridge, the tool changer, and even many of the available options. Thus, they are both very comparably priced, and offer very similar performance and value. What differentiates the S-Series from it's Super Duty Series sibling is not in it's parts or components, but in it's table layout. The S-Series design moves a single table in the longer direction, so its bridge need only span the shorter dimension across the width of the table. The shorter bridge can have more rigidity by spanning a shorter distance, however, the floor space required is greater. The main advantage of the S-Series design is the three-sided access to the table. This can be a material handling advantage for some applications and products. Unobstructed table access makes loading and unloading of large workpieces or tooling more convenient, & allows for the easy integration of material handling systems, transfer tables, and other automation alternatives. This design also works very well with Roller Hold Down systems for stack cutting of multiple whole sheets of material. Lastly, this machine has a longer and more narrow footprint, which can be the perfect fit in some production settings, whereas other designs may not as easily fit into the existing production work flow. The S-Series is available in both single table and dual table designs to suite your manufacturing requirements. For more information on this line click HERE.

98S

122S

146S

3-Axis Fixed Bridge // Dual Process Series - 2 Spindle Standard

Imagine that you could take the heaviest, fastest and highest performing machine available in the world at any price and then double its performance. What if you could get the throughput of two complete machines out of a single machine footprint? How would you like the flexibility of being able to run two completely different programs at the exact same time on only one machine? Or to run two identical parts at the same time? With the optional C.R. Onsrud Multi-Head Dual Process Technology, you can do all of this and more. Start with any Standard C.R. Onsrud Extreme Duty Series twin table model. Then add a second tool changer, a second main router spindle and our optional Individual Servo Control of Second Complete Spindle Slide from our list of available standard machine options. When teamed up with the dual process power and capabilities standard in our OSAI controller, you get our Multi-Head Dual Process Technology. Even additional drilling or boring blocks, aggregate tool changers or multiple c-axis can be added as options. In fact, this option is so flexible that the two heads could even be configured entirely differently! For more information on this line click HERE.

98HD

122HD

148HD

194HD

244HD

3-Axis Fixed Bridge // Custom Machines

C.R. Onsrud's Custom Machines ...For more information on this line click HERE.

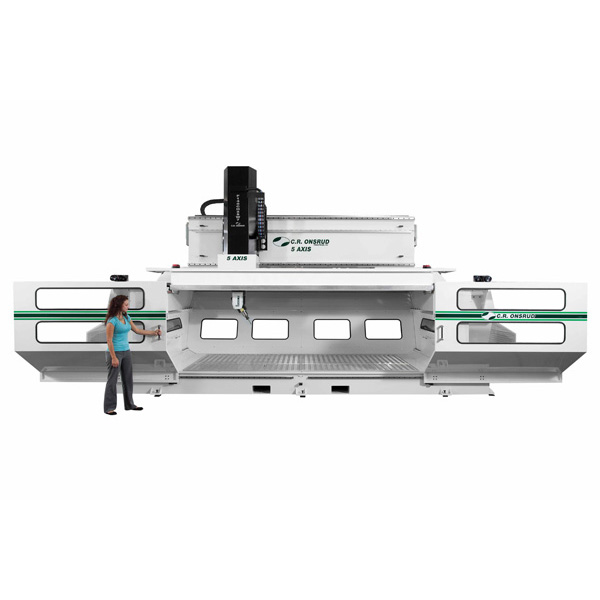

5-Axis Gantry // 5-Axis Pro Series

Onsrud engineers many of our frame components to be used cross-platform in our 3, 4, or 5-Axis Models. By utilizing standard frames, parts and electronics, Onsrud was able to leverage the economies of scale present in our 3 and 4-Axis machine sales, and dramatically lower the overall price point of our 5-Axis models, without compromising performance or value. For example, almost all of the parts on a 5-Axis Extreme Series are also used on the 3 or 4-Axis Extreme Series; and, many of the parts on the 5-Axis Pro Series are also used on the 3 or 4-Axis Pro Series. Of course the heads are different and the frames are taller and wider on the 5-Axis machines, but the machine uses many of the same standard components, with the same off the shelf, readily available, non-proprietary, and proven parts. The one-piece thick-wall engineered steel base of the 5-Axis Wide Pro Series was specially engineered with internal steel reinforcements. It is designed to handle the extreme weights of large blocks of non-ferrous metal, large tooling or fixtures for composites and sheet metal parts. You will be able to stack cut aluminum skins, or even the large and thick assemblies we tackle in the RV, marine, and aircraft industries. After being welded into a single structure, the machine base is heat treated and slowly cooled to create a stress free, normalized and lasting machining platform. Then the precision machining for all of the critical components is accomplished in one set- up, with all of the operations performed on the same face, to guarantee machined-in accuracy and stability. This base also incorporates the top-rail design of the Pro Series which allows for shorter and stubbier one- piece steel vertical columns, which are more rigid and have more leverage over the bridge than other side rail designs. Lastly we use large vertical Z-Axis rams with large bearing spacing for increased rigidity, fast positioning, and smooth accurate cutting. The result is a high precision machine that handles the largest workpieces, and the heaviest materials and tooling, offers unique automation and material handling options, and provides the best possible cost per table size relationship available. If you do not have unlimited time to wait for your machine to finish, and are picky about your part’s fit, and finish then do not just buy the cheapest 5-Axis Machine you can find. Be more demanding, and expect the highest possible accuracies, at the fastest feed rates that the tooling can sustain, without chatter, or melt back all over a part. With a little research, you will find that Onsrud offers an incredible 5-Axis value for the performance and capability the machine delivers. Investigate for yourself how our philosophy of standardization allows Onsrud to offer custom-sized large-format moving gantry 3, 4, and 5-Axis CNC Routers at standard machine prices, with the reliability and parts availability of standard machines. For more information on this line click HERE.

F121G

F168G

F216G

F300G

F480G

5-Axis Gantry // 5-Axis Wide Pro Series

Onsrud engineers many of our frame components to be used cross-platform in most of our 3, 4, or 5-Axis Models. By utilizing standard frames and standard parts & electronics, Onsrud is able to leverage the economies of scale present in our 3 & 4 axis machines, and lower the overall price point of our "Specialised" 5-Axis models, without compromising performance or value. For example, many of the parts on a 5-Axis Extreme Duty Series are also used on the 3 or 4 Axis Extreme Duty Series; and, many of the parts on the 5-Axis Pro Series are also used on the 3 or 4 Axis Pro Series. The heads are different & the frames are taller and wider on the 5-Axis machines, but the machine uses many of the same standard components, with the same, readily available, non-proprietary, & proven parts. The one-piece, thick-wall engineered steel base of the 5-Axis Wide Pro Series, was specially designed and FEA Engineered, with critical internal steel reinforcements. It is designed to handle the extreme weights of large blocks of non-ferrous metal, over-sized tooling or fixtures for composites, and sheet metal parts. You'll be able to stack cut aluminum skins, or even the large and thick assemblies we tackle in the RV, marine, and aircraft industries. After being welded into a single structure, the machine base is heat treated and cooled under strict controls, to create a stress free, normalized, and lasting machine platform. The precision machining for all of the critical components is, then, completed in one set-up, with all of the operations performed on the same face, to guarantee machined-in accuracy and stability. This base also incorporates the top-rail design of the Pro Series which allows for shorter & stubbier one-piece steel vertical columns, which are stiffer and have more leverage over the bridge than other side rail designs. Lastly we use large vertical Z-Axis rams with extra wide bearing spacing for increased rigidity, fast positioning, and smooth accurate cutting. The result is a high precision machine that handles the largest workpieces, deals with the heaviest materials and tooling. Onsrud also offers unique automation and material handling options, and provides the best possible cost per table size relationship available. If you don't have all day to wait for your machine to finish, and are particular about your part's look & fit, then don't just go out and buy a "budget" 5-Axis Machine. Be more demanding, and expect the highest possible accuracies, at the fastest feed rates that the tooling can sustain. With a little research, you'll find that Onsrud offers an incredible 5-Axis value for the performance & capability the machine delivers. Investigate for yourself how our philosophy of standardization allows Onsrud to offer custom-sized, large-format moving gantry 3, 4, & 5 Axis CNC Machines at standard machine prices; along with the reliability and parts availability of standard machines. For more information on this line click HERE.

Wide Pro 8

Wide Pro 10

Wide Pro 12

5-Axis Gantry // 5-Axis Compact High Rail Series

The design of the C.R. Onsrud Compact High Rail Series machines specifically addresses the needs of non-ferrous metals, plastics, composites, and light steel; whether wet or dry cutting. The CH Series provides many of the same advantages as our HR Series, such as a large volumetric machining envelope; but with a much more compact footprint. It has the additional advantage of a self-supportive one-piece design, that allows most sizes of this machine to ship fully assembled and nearly functional; allowing you to be up-and-running, producing parts immediately. The set-up and install are minimal because there is practically no assembly required. The compact and sturdy design not only respects your expensive shop floor space, but usually requires no additional floor preparation or modification potentially saving unforeseen or costly integration and facilities costs. This intelligent design begins with a stand-alone, machine base and foundation. This heavy, one-piece thick-wall, engineered steel base with internal steel reinforcements forms a machine bed that can easily handle the extreme weights of large blocks of non-ferrous metal, over-sized tooling or fixtures for composites, and sheet metal parts. The base also bears and strengthens two rows of heavy steel support walls onto which the X-Axis guide ways and drive systems are mounted. A massive moving bridge featuring over three foot bearing spacing spans these stationary support walls to form the Y-Axis. Electronically tensioned, dual drives on each end of this bridge allow for smooth, fast, precise, and back- lash free motion. This design allows the electronics and mechanical drives to be located completely outside of the machining envelope and prevents their potential contamination from wet or dry machining. This design eliminates the vertical pillars present in many other moving bridge machines. Eliminating the vertical columns minimizes potential frame deflection or distortion, and increases overall volumetric accuracy. This design also allows for the more efficient and more rapid movements of a substantially larger and heavier bridge, and for the use of a much taller and stiffer z-ram. A taller Z-Axis cutting envelope is made possible, and the machine is able to be more rigid and more accurate at these taller working heights. You can immediately see the attention to detail, and how concerned the Onsrud engineers are with safety and usability. As a result of these concerns, side panels and doors enclose the working envelope to help ensure maximum operational and environmental safety, reduced noise levels, and to control debris. You notice the attention to detail when the doors open up far enough to provide full access to the machine bed. When contamination concerns are more vital, the optional retractable bellows roof can fully protect the surrounding environment from fine airborne particulate or contamination. The roomy open design gives easy unobstructed access with a forklift or overhead crane. For more information on this line click HERE.

W7

W10

5-Axis Gantry // 5-Axis High Rail Series

The Introduction of the Five Axis High Rail Gantry Series machining centers and mills signifies C.R. Onsrud's continued and growing commitment to the advanced materials industry. The HR Series was designed and built with a focus on the needs of manufacturers to produce high precision non- ferrous, light ferrous, or composite products that require a sizable working envelope to accommodate their large sizes or awkward shapes. To this end; Finite Element Method design, and Finite Element Analysis was performed extensively throughout the design and engineering processes. Thus, you can be confident that this machine will provide the accuracy, repeatability, speed, structural rigidity, and high material removal rates demanded when machining structural aluminum components, aircraft surface skins, automotive molds, helicopter blades, plugs for boat molds, and structured insulated panels just to name a few examples. C.R. Onsrud High Rail Gantry machines feature a unique frame design that specifically addresses the needs of non-ferrous metals, plastics, composites, and light steel; whether wet or dry cutting. Two rows of heavy steel support pillars are joined at their precision machined shoulders, forming support walls, onto which the X-Axis guide ways and drive systems are mounted. A massive moving bridge featuring over 4-foot bearing spacing, spans these stationary support walls to form the Y-Axis. Electronically tensioned, dual synchronous direct drives on each end of this bridge allow for smooth, fast, precise, and back-lash free motion. This design allows the electronics and mechanical drives to be located completely outside of the machining envelope and prevents their potential contamination from wet or dry machining. This design also eliminates the vertical pillars present in many other moving bridge machines. Eliminating the vertical columns minimizes potential frame deflection or distortion, and increases overall volumetric accuracy. This design also allows for the more efficient and more rapid movements of a substantially larger and heavier bridge; and for the use of a much taller and stiffer z-ram. A taller Z-Axis cutting envelope is made possible, and the machine is able to be more rigid and more accurate at these taller working heights. Safety and usability have always been hallmarks of Onsrud machining centers. As a result of these concerns, side panels and doors completely surround the working envelope to help ensure safe operation, reduced noise levels, and to control debris. When contamination concerns are more critical, the optional retractable bellows roof can fully protect the surrounding environment from fine airborne particulate or contamination. Also, there are optional lighting, down-draft dust collection systems, and auger or conveyor systems, making it possible to better control and capture most of the dust and particles. The roomy open design gives easy unobstructed access with a forklift or overhead crane. With our largest variety of options, sizes, upgrades, and possibilities, the flexible High Rail Gantry series is built and engineered-to-order, around your products, your requirements, and your needs. The High Rail Gantry makes use of the foundation and floor of your facility, to deliver the heaviest bed load capacities available on any design. The floor inside the machine is left free and uncluttered, ready for any table, tooling, fixture, clamping, or POGO part holding system. Various table options include Above Floor Roll- In, Above Floor Fixed, Flush Mounted or Pit, Aluminum T-slot, Steel T-Slot, Drilled and Tapped, Slab Plate, Magnetic, or Vacuum. Multiple spindle options range from higher RPM lower torque routing spindles to lower RPM higher torque milling spindles with flood, mist, dry, or near-dry capabilities. Large capacity automatic tool changers are available with HSK-63F or HSK-63A tooling. The High Rail Gantry is available with open architecture controllers from OSAI or FANUC, to deliver the best 5-Axis machine motion and the most programming capability and flexibility. Both available controller options include Tool Center point Programming (TCP) and High Speed Machining (HSM) as standard. And, all of the controller options are compatible with optional volumetric laser compensation and accuracy enhancing linear scales on all axes. For more information on this line click HERE.

5-Axis Gantry // Custom Machines

C.R. Onsrud's Custom Machines is ...For more information on this line click HERE.

5-Axis Bridge // 5-Axis Extreme Duty Series

The Super Heavy Duty - yet super fast - 5 Axis Series CNC Routers carry the "No Compromises" design of our Extreme Duty machines to the next logical, power-production level. Ranging from the twin table, fixed bridge models of the HD series to the moving gantry machines with super-large 15ft x 60ft fixed tables, you won't find a heavier, faster, higher performing machine anywhere - at any price. On the fixed bridge HD Series, Onsrud starts with the largest standard cast iron frame offered anywhere in the marketplace today. The massive cast iron bridge on the HD Series has over double the cast iron of even our legendary C Series models. The massive cast iron frame is then mated to our one-piece, self-supportive, heat- treated, stress-relieved and normalized, internally-reinforced, thick-walled, tubular steel base for unrivaled weight, mass, rigidity, durability and super fast feeds and speeds. All C.R. Onsrud 5-axis machines have large vertical rams and servos for fast positioning and smooth cutting. C.R. Onsrud 5-axis machines are faster, smoother and far more rigid than our competitors' comparable machines. For more information on this line click HERE.

F74HD

F98HD

F122HD

F148HD

F194HD

5-Axis Bridge // 5-Axis S Series

The 5-Axis S-Series CNC Router by C.R. Onsrud is designed to be a more cost effective 5-Axis CNC machining center solution. The S-Series CNC features a welded steel frame that is heat-treated, stress-relieved and normalized, for unrivaled weight, mass, rigidity, durability, feeds and speeds at this price point. The frame has been designed and checked with industry leading ANSYS FEA software to ensure the most rigid design in its class. The S-Series is designed for those that want to save cost and do not need the extra mass and rigidity of a cast iron bridge or the extra speed and flexibility of a twin table design. The F122S comes standard with a 12HP, 20,000 RPM spindle, which can be upgraded to a 15HP, 22,000 RPM spindle. The compact 5-Axis spindle design is ideal for trimming composite, thermoformed, and fiberglass parts, along with custom mill work, mold making, or any other application where space may be limited but cut quality is essential. For more information on this line click HERE.

F62S

F122S

F146S

5-Axis Bridge // 5-Axis Dual Process Series

Imagine that you could take the heaviest, fastest and highest performing machine available in the world at any price and then double its performance. What if you could get the throughput of two complete machines out of a single machine footprint? How would you like the flexibility of being able to run two completely different programs at the exact same time on only one machine? Or to run two identical parts at the same time? With the optional C.R. Onsrud Multi-Head Dual Process Technology, you can do all of this and more. Start with any Standard C.R. Onsrud 5-Axis Extreme Duty Series or 5-Axis Hybrid Mill twin table model. Then add a second tool changer, a second main router spindle and our optional Individual Servo Control of Second Complete Spindle Slide from our list of available standard machine options. When teamed up with the dual process power and capabilities standard in our OSAI controller, you get our Multi-Head Dual Process Technology. In fact, this option is so flexible that the two heads could even be configured entirely differently! For more information on this line click HERE.

F98HD

F122HD

F148HD

F194HD

5-Axis Bridge // 5-Axis Hybrid Mill - Dual Process Available

A CNC machine tool that combines the best qualities of the CNC Router and the CNC Mill, deserves it's own unique classification. So, what's a suitable name for this group of machines? Since it's More than a mill, certainly not just a router, and doesn't fit into any existing machine categories or descriptions; the Hybrid Mill creates a class all it's own. It would be understating the Hybrid Mill to classify it as just an Elite CNC Router. To start with, the Hybrid Mill boasts a much larger frame, wider bearing spacing, heavier components, and tighter tolerances than are found on even the most "elite" CNC Routers. Unlike Routers, the Hybrid Mill also comes fully enclosed and ready for wet, dry, mist, or MQL machining with options for flood coolant either around the tool, or through the tool. Like the Hybrid Mill, Routers boast flexible and innovative universal vacuum part holding methods, quick set-ups & tear-downs, and very attractive pricing. A Hybrid Mill also has options for t-slot tables, custom bolt patterns, or steel tables. So, it delivers the part holding flexibility as a router, but with the increased table load-bearing capability required for larger and heavier work-pieces & tooling. With up to twin 33HP spindles, twin 24 position HSK-63A dual arm rapid changers available, and a frame engineered to be large enough & rigid enough to handle it all; a Hybrid Mill far exceeds the capabilities of routers. But, just calling this machine a Mill, doesn't give you an accurate expectation of its flexibility & capabilities. Mills typically have many limitations that by design, a Hybrid Mill doesn't. Hybrid Mills aren't limited by small table sizes & restricted work envelopes. Twin tables with pendulum processing for 100% spindle utilization are standard. Plus, the smallest table sizes offered on a Hybrid Mill are over 5 feet by 8 feet with over 3 feet of Z clearance. This provides a standard work envelope that's larger than what would be optional on all but the most expensive of high end milling machines. Mills are often characterized by their high torque, low RPM spindles and their highly accurate but sometimes slow feed rates. Hybrid Mills provide the High Torque necessary for machining all non-ferrous materials, advanced composites, & many ferrous metals, but without sacrificing the high RPM that are sometimes necessary for High Speed machining of aluminums, fiber reinforced plastics, PVC, carbon fiber, graphite, a-cell, phenolic, and many more materials. Wet or dry machining of composites, ferrous, and non-ferrous materials has never been easier, faster, or more cost effective. For more information on this line click HERE.

F98HM

F148HM

5-Axis Bridge // Custom Machines Series

C.R. Onsrud's Custom Machines ...For more information on this line click HERE.